Blog

Atex 13 Amp 3 Pin Sockets Sockets

Introduction to Atex 13 Amp 3 Pin Sockets Sockets

Atex 13 Amp 3 Pin Sockets Sockets are specialized electrical connectors designed for use in potentially explosive atmospheres, commonly found in various industrial settings. The term “Atex” is derived from the French term “Atmosphères Explosibles,” which refers to equipment and protective systems intended for use in hazardous environments. These sockets are crucial in ensuring safety and preventing accidents in areas where flammable gases, vapors, or dust may be present.

The primary purpose of Atex certification is to ensure that products meet stringent safety standards to minimize the risk of igniting hazardous substances. This certification is essential for manufacturers and end-users alike, as it signifies compliance with European Union regulations (specifically the Atex directive) that govern equipment intended for use in potentially explosive atmospheres. The Atex 13 Amp 3 Pin Sockets Sockets are built to withstand harsh conditions while providing reliable electrical connections without compromising safety.

These sockets play an integral role in various applications, including oil and gas, petrochemical industries, and wastewater facilities. Their design includes features that prevent the ingress of harmful materials and reduce the chances of electrical arcing, which could lead to explosions in dangerous environments. The 3-pin configuration allows for secure connections, making them suitable for powering tools and equipment in locations where standard electrical infrastructure may not be safe or adequate.

In summary, Atex 13 Amp 3 Pin Sockets Sockets are pivotal in enhancing the safety and reliability of electrical systems in hazardous areas. By adhering to Atex standards, manufacturers ensure that these sockets can operate effectively in environments where safety is paramount, creating confidence for operators and contributing to the overall integrity of industrial processes.

The Importance of Atex Certification

Atex certification is a critical aspect of ensuring safety in hazardous areas where explosive atmospheres may occur. The Atex directive, established by the European Union, mandates that equipment intended for use in explosive environments must meet stringent safety standards. The aim of these regulations is to minimize the risk of ignition that could lead to fires or explosions, which is particularly essential in industries such as oil and gas, chemical manufacturing, and mining, where flammable materials are prevalent.

To achieve Atex certification, electrical equipment—including 13 amp 3 pin sockets—must undergo rigorous testing and should adhere to specific criteria that demonstrate their reliability and safety. These criteria encompass various parameters, including temperature ratings, resistance to mechanical stress, and the capability to contain internal explosions without propagating them to the external environment. Only sockets that meet or exceed these strict standards can display the Atex mark, signifying compliance with the directive.

The selection of Atex-certified sockets is paramount for organizations operating in hazardous areas, as using non-compliant equipment can lead to severe consequences, including workplace accidents and legal repercussions. Additionally, Atex certification assures operators and safety personnel that the equipment is reliable and suitable for the challenging conditions found in these environments. Beyond compliance, Atex certification reflects a commitment to safety and risk management, enhancing the overall operational integrity and productivity of facilities in hazardous sectors.

In conclusion, the significance of Atex certification cannot be overstated, as it directly impacts the safety and reliability of electrical equipment in explosive atmospheres. Organizations must prioritize equipment that meets these rigorous standards to ensure not only compliance but also the safety of personnel and infrastructure in hazardous areas.

Features of Atex 13 Amp 3 Pin Sockets Sockets

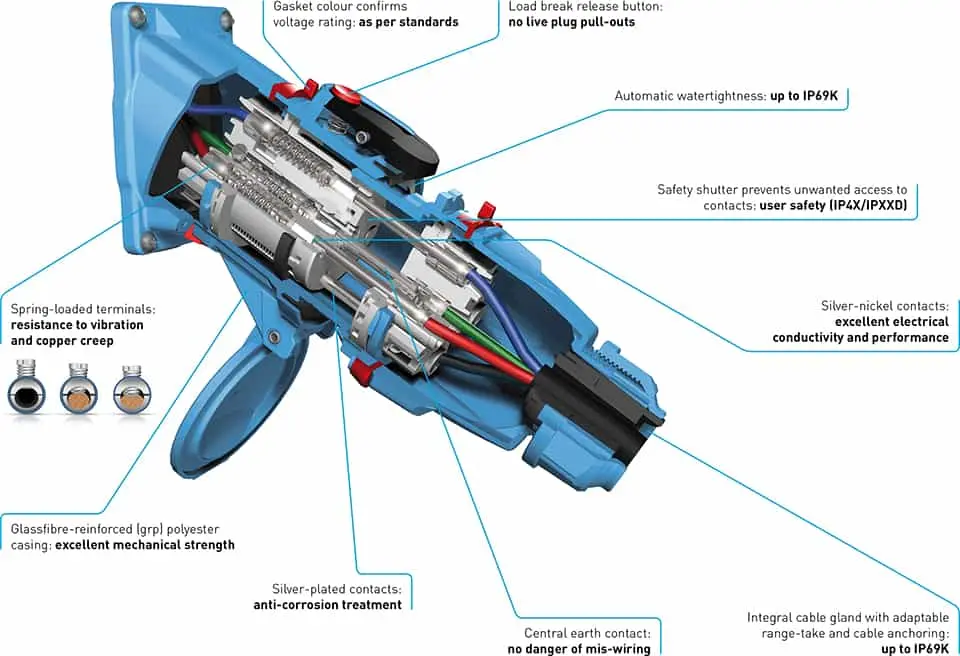

Atex 13 Amp 3 Pin Sockets Sockets are specifically designed for use in hazardous environments, providing essential safety and functionality. One of their standout features is the plug-and-play design, which facilitates easy installation and maintenance. This design means that users can connect devices swiftly without the need for complex wiring or tools, ensuring minimal downtime in critical situations. This aspect is particularly beneficial in industries where safety and efficiency are paramount.

Additionally, Atex 13 Amp sockets incorporate an integrated load-break switch, a crucial element that enhances safety. This switch allows users to safely disconnect the power supply without the need to unplug devices directly. By doing so, it significantly reduces the risk of arcing—a common hazard in explosive atmospheres—thereby safeguarding personnel and equipment. This functionality is vital in maintaining operational safety in volatile settings.

Waterproofing is another prominent feature of these sockets. Constructed to meet stringent environmental standards, Atex 13 Amp sockets are rated to withstand moisture ingress, making them suitable for outdoor and damp locations. The robust design ensures that water and other contaminants do not compromise the integrity of the electrical connection, which is critical in preventing short circuits and electrical failures in hazardous areas.

Lastly, these sockets offer dual voltage capabilities, allowing for versatile use with different power systems. This adaptability means that one socket can support various equipment types, accommodating diverse operational needs without requiring additional sockets. The combination of these features—plug-and-play convenience, integrated load-break switch, waterproof design, and dual voltage support—cements Atex 13 Amp 3 Pin Sockets Sockets as reliable solutions for enhancing safety and efficiency in hazardous environments.

Applications of Atex 13 Amp 3 Pin Sockets Sockets

Atex 13 Amp 3 Pin Sockets find extensive applications across various industries, particularly in sectors characterized by hazardous environments. One of the most prominent industries using these specialized sockets is the oil and gas sector. Given the inherent risks associated with flammable substances, Atex-rated equipment, including these sockets, becomes indispensable for ensuring safety during operations. For instance, offshore oil rigs often employ Atex 13 Amp 3 Pin Sockets Sockets to power essential equipment in areas where ignitable gases may be present, effectively reducing the risk of electrical mishaps.

Similarly, the chemical processing industry is another key domain where Atex 13 Amp 3 Pin Sockets Sockets play a critical role. In facilities where reactive chemicals are manufactured or stored, these sockets provide a secure method of powering machinery and equipment. Their design prevents the ignition of explosive vapors, making them ideal for environments classified as Zone 1 and Zone 2. Real-world applications include their use in mixing and processing stations, where consistent and reliable power supply is crucial for maintaining the safety and efficiency of operations.

Furthermore, in offshore environments, such as those associated with wind farms and underwater installations, Atex 13 Amp 3 Pin Sockets Sockets are essential for ensuring operational integrity and safety. These environments pose unique challenges due to their exposure to harsh weather and potential for explosive atmospheres. The sockets’ durability and resistance to corrosion ensure that equipment remains functional even in tough conditions, enabling uninterrupted service delivery.

Overall, Atex 13 Amp 3 Pin Sockets Sockets are integral components in hazardous industries, enhancing both safety and operational reliability. Their specialized design, tailored for environments where risks are prevalent, allows various applications to thrive without compromising on safety standards.

Comparing Atex Sockets to Traditional Sockets

Atex 13 Amp 3 Pin Sockets Sockets are specifically designed to provide safe and reliable electrical connections in hazardous environments, making them a crucial component in many industrial settings. Unlike traditional plugs and sockets, which are suitable for general use, Atex sockets are engineered to prevent ignition sources in potentially explosive atmospheres. This distinctive feature of Atex sockets enhances safety in locations where flammable gases, vapors, or dust may be present, significantly reducing the risk of accidents and ensuring compliance with safety regulations.

One of the key differentiators between Atex sockets and their traditional counterparts is their construction. Atex sockets are built with robust materials that can withstand harsh conditions, pressure, and chemical exposure. This durability ensures long-term reliability, even in extreme environmental circumstances. In contrast, standard sockets may deteriorate over time, increasing the likelihood of failure and the subsequent risk of electrical hazards. Furthermore, traditional sockets typically lack the stringent safety certifications required for use in hazardous zones, which can lead to dire consequences if employed improperly. Thus, Atex sockets are undeniably the superior choice for ensuring safety in challenging environments.

When evaluating cost-effectiveness, there may be an initial price disparity between Atex sockets and conventional alternatives. However, the investment in Atex sockets often offsets potential losses arising from workplace incidents, equipment damage, or downtime caused by electrical failures. Additionally, their robust design and the ability to prevent ignition sources minimize liability concerns and insurance costs for businesses operating in hazardous areas. In essence, while the upfront costs may be higher, the long-term benefits of safety, reliability, and compliance with regulations render Atex 13 Amp 3 Pin Sockets Sockets a prudent choice over traditional options in hazardous settings.

Benefits of Using Atex Isolation Switches

Atex isolation switches play a critical role in enhancing the safety and reliability of Atex 13 Amp 3 Pin Sockets Sockets, particularly in hazardous areas where flammable gases or dust may be present. These switches are designed to provide a means for safe disconnection of electrical equipment without the risk of sparking or triggering an explosion. In environments where combustible materials are prevalent, having a reliable switching mechanism is imperative. Atex isolation switches facilitate quick and safe equipment disconnection, which is essential during emergencies or routine maintenance operations.

One of the main benefits of Atex isolation switches is their ability to isolate circuits effectively. This isolation ensures that power is completely cut off from the equipment before any maintenance work begins, thus minimizing the risk of electric shock or equipment damage. Furthermore, these switches are designed to handle high-voltage loads while maintaining operational integrity in high-risk environments. This feature elevates their effectiveness as safety devices and allows workers to conduct maintenance with confidence.

Additionally, Atex isolation switches contribute to compliance with safety regulations that govern hazardous locations. By integrating these switches into electrical systems that utilize Atex 13 Amp 3 Pin Sockets Sockets, organizations can meet necessary safety standards and reduce the potential for accidents. The robust design of these switches also means they can withstand harsh environmental conditions, thereby ensuring long-term reliability and performance.

Moreover, the implementation of isolation switches enhances operational efficiency. In situations where equipment needs to be frequently disconnected for maintenance or inspections, these switches provide a straightforward and swift disconnection process. Overall, the benefits of employing Atex isolation switches extend beyond safety – they facilitate regulatory compliance, ensure operational longevity, and protect personnel working in hazardous environments. In conclusion, the strategic use of these switches in conjunction with Atex 13 Amp 3 Pin Sockets Sockets is vital for promoting a safe and reliable working atmosphere.

Technical Considerations for Selecting Atex Sockets

When selecting Atex 13 Amp 3 Pin Sockets Sockets, various technical factors must be analyzed to ensure safety and reliability in hazardous areas. Primarily, one must consider the current capacity of the sockets. Atex sockets are designed to handle specific loads, and ensuring that the selected socket can accommodate the expected current is crucial to prevent overheating and potential fire hazards. Typically, a 13 Amp socket is suitable for standard applications; however, if higher loads are expected, alternative models should be evaluated.

Voltage ratings are another significant consideration. It is essential to verify that the chosen Atex socket matches the voltage levels of the application. For instance, Atex sockets are available in different voltage ratings, including 240V and 415V, depending on the operational requirements. Selecting a socket with an appropriate voltage rating is vital to safeguard against electric shock and equipment damage.

Environmental conditions play an equally important role in the choice of Atex sockets. Factors such as ambient temperature, humidity, and potential exposure to corrosive substances can affect the socket’s performance and longevity. It is crucial to choose a socket rated for the specific environmental challenges it will face, including those adhering to designated Atex Zone classifications. Furthermore, assessing the ingress protection (IP) rating ensures that the socket is adequately protected against dust and water ingress.

Installation requirements must also be taken into account. Atex sockets should be installed according to the manufacturer’s guidelines and local regulations, ensuring compliance with safety standards. Proper installation practices not only enhance reliability but also extend the service life of the socket. Overall, careful consideration of current capacity, voltage ratings, environmental conditions, and installation requirements is paramount for selecting appropriate Atex 13 Amp 3 Pin Sockets Sockets for hazardous areas.

Maintenance and Testing of Atex 13 Amp 3 Pin Sockets Sockets

Regular maintenance and testing of Atex 13 Amp 3 Pin Sockets Sockets are crucial to ensure their continued safety and reliability, particularly in hazardous environments. Such environments often expose electrical installations to conditions that can lead to degradation, compromising functionality and risking safety. Consequently, implementing a structured maintenance protocol is essential for mitigating potential hazards.

The frequency of maintenance checks should be determined by the specific conditions of the site and the performance history of the sockets. Generally, it is recommended to conduct inspections at least annually, or more frequently in environments with high levels of dust, moisture, or chemical exposure. During these inspections, visual assessments should be performed to identify any signs of wear, corrosion, or physical damage to the sockets and surrounding infrastructure.

In addition to routine visual inspections, functional testing of Atex 13 Amp 3 Pin Sockets Sockets is also necessary. This includes testing for continuity, insulation resistance, and verifying that the sockets operate under their rated load without overheating or showing performance irregularities. Utilizing calibrated testing devices ensures the accuracy of the results. Furthermore, these checks should be documented meticulously to establish a reliable maintenance history, which is essential for compliance with safety standards and regulations.

Adhering to manufacturer’s guidelines is vital during the maintenance process, as they often provide specific instructions on the care and operation of their products. Training personnel on proper testing and maintenance procedures is also important to ensure a comprehensive understanding of best practices. By prioritizing regular maintenance and systematic testing of Atex 13 Amp 3 Pin Sockets Sockets, organizations can significantly enhance operational safety and extend the lifespan of their electrical equipment, thereby delivering reliable performance in hazardous areas.

Conclusion: The Future of Atex 13 Amp 3 Pin Sockets Sockets

In reviewing the importance of Atex 13 Amp 3 Pin Sockets Sockets, it is essential to acknowledge their critical role in ensuring safety and reliability in hazardous areas. Throughout this blog post, we have explored various factors that contribute to the effectiveness of these electrical sockets, such as their design principles, compliance with Atex directives, and the inherent protective features that mitigate risks associated with explosive atmospheres. As technology progresses, the demand for enhanced safety measures in industrial environments remains paramount.

Future developments in Atex 13 Amp 3 pin socket technology are anticipated to focus on increasing durability while reducing environmental impact. Innovations in materials science may yield more robust options that can withstand harsh conditions typically found in hazardous areas. Additionally, smart technology integration presents the potential for real-time monitoring and diagnostics, which can further improve operational safety and efficiency. By harnessing advancements in IoT and automation, Atex sockets could evolve into more intelligent systems capable of alerting users to potential hazards before they occur.

Moreover, the increasing scrutiny of safety regulations will undoubtedly influence the design and production of Atex equipment. Manufacturers will need to stay abreast of the latest compliance standards to ensure their products not only meet but exceed safety expectations. This ongoing commitment to adherence will foster trust among users who rely on Atex 13 Amp 3 Pin Sockets Sockets in their operations. Ultimately, the combination of safety, reliability, and innovation will define the future landscape of electrical equipment used in hazardous locations.

In conclusion, as we look forward to advancements in technology and regulations, the importance of Atex 13 Amp 3 Pin Sockets Sockets in safeguarding personnel and infrastructure in hazardous areas cannot be overstated. Embracing these changes will ensure that safety remains at the forefront of electrical equipment selection, facilitating progress in industries where such considerations are vital.