Blog

Cooper Bussmann Inverter: Advanced Circuit Safety Solutions

Cooper Bussmann and Inverter Protection: Advanced Circuit Safety Solutions

Introduction to Power Electronics Protection

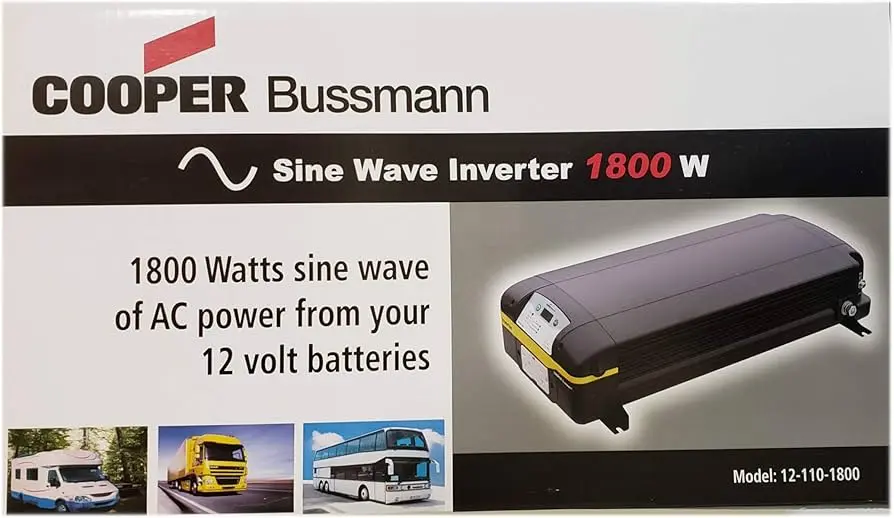

In the rapidly evolving world of power electronics, circuit protection plays a crucial role in ensuring system reliability and safety. Cooper Bussmann Inverter, while not manufacturing inverters directly, has established itself as a cornerstone in providing sophisticated protection solutions for inverter applications.

Understanding Circuit Protection in Modern Inverters

Fundamental Protection Requirements

- Overcurrent Protection

- Fast response time

- Precise trip characteristics

- Coordination capabilities

- Reset functionality

- Temperature stability

- Voltage Protection

- Surge suppression

- Transient protection

- Overvoltage prevention

- Undervoltage monitoring

- Harmonic mitigation

Cooper Bussmann’s Protection Portfolio

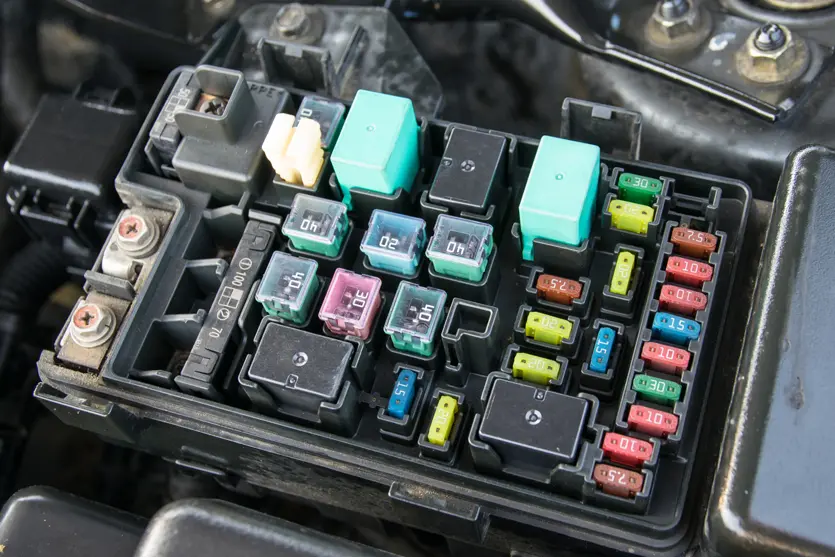

Fuse Technologies

- Semiconductor Fuses

- Ultra-fast response

- Precise I²t ratings

- Low power losses

- High breaking capacity

- Temperature compensation

- DC Fuses

- High voltage ratings

- Arc interruption capability

- Compact design

- Multiple mounting options

- Status indication

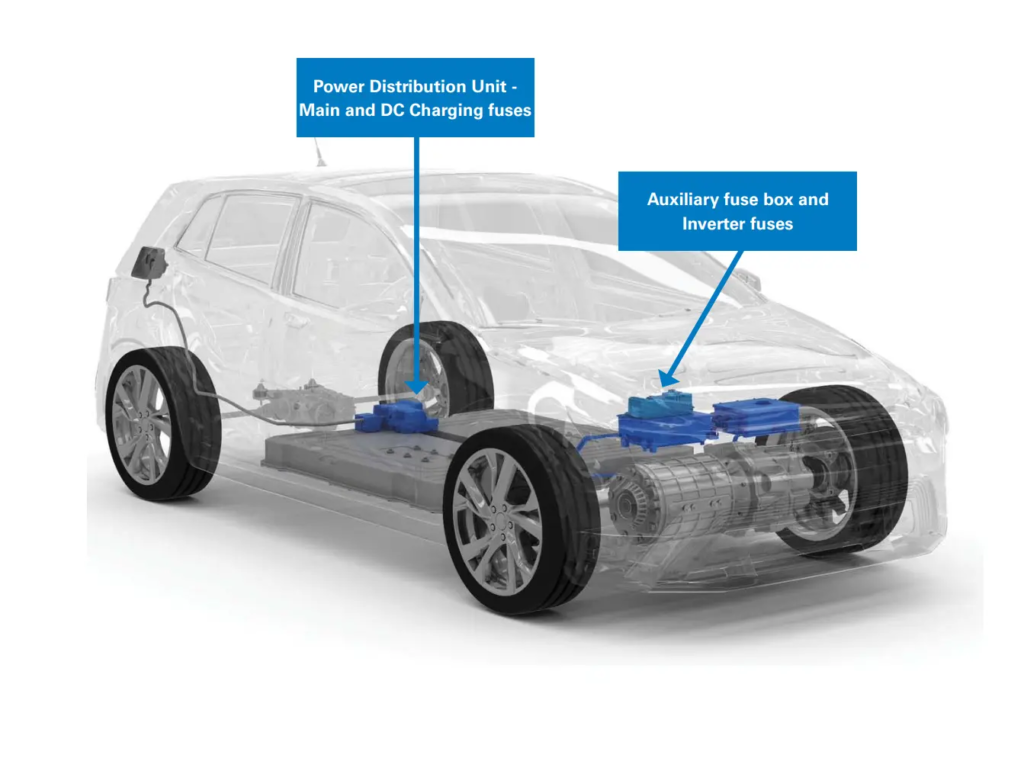

Application in Inverter Systems

Power Stage Protection

- Input Protection

- DC bus protection

- Reverse polarity prevention

- Inrush current limiting

- Ground fault detection

- Surge protection

- Output Protection

- Short circuit protection

- Overload management

- Phase loss detection

- Thermal monitoring

- Harmonic filtering

Technical Specifications and Standards

Certification Requirements

- International Standards

- UL certification

- CE marking

- IEC compliance

- CSA approval

- Regional requirements

- Performance Criteria

- Breaking capacity

- Voltage rating

- Current rating

- Operating temperature

- Response time

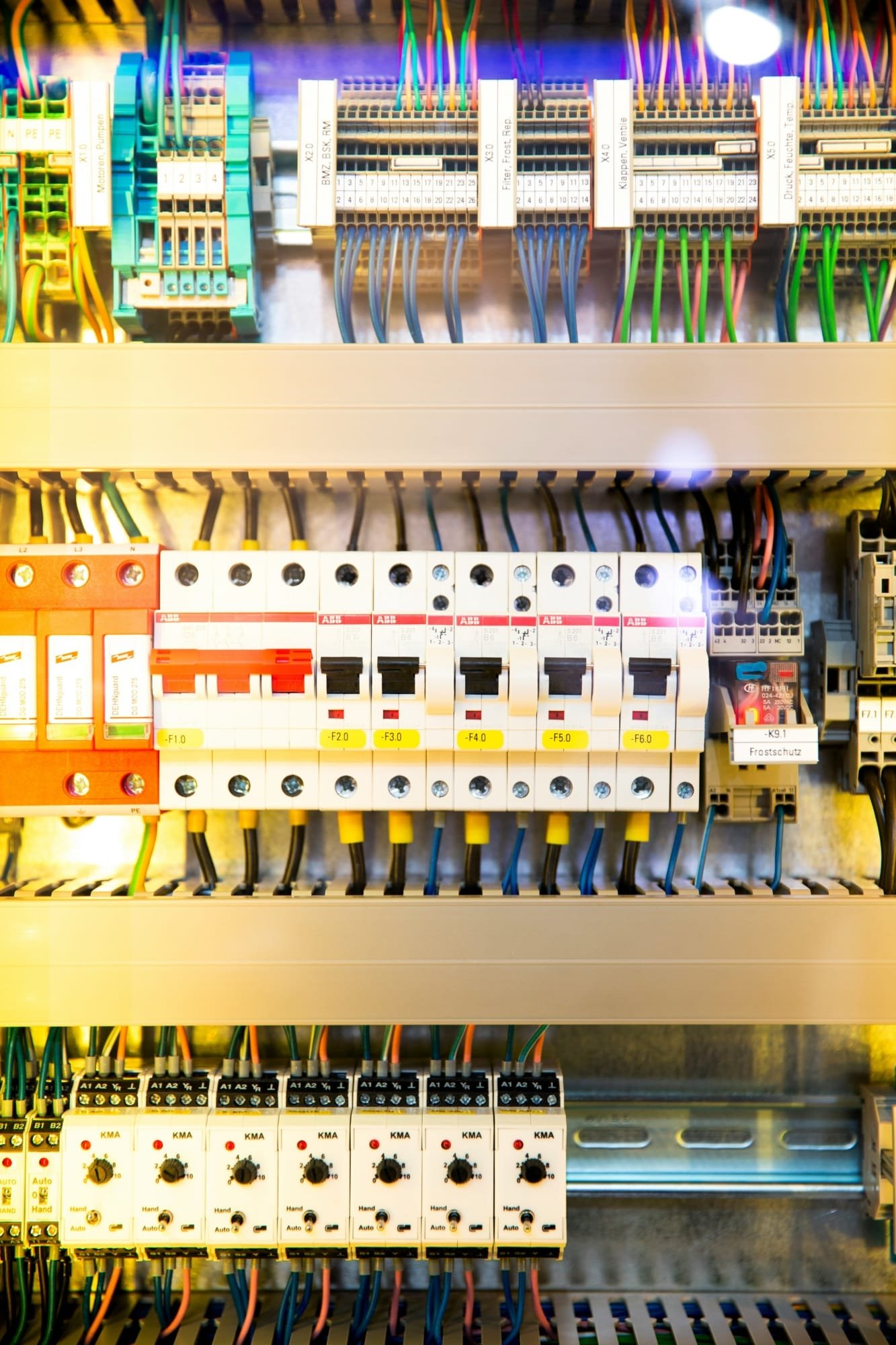

Design Considerations

Protection Coordination

- System Integration

- Selective coordination

- Cascading protection

- Backup protection

- Time-current coordination

- Energy limiting

- Environmental Factors

- Temperature derating

- Altitude considerations

- Humidity effects

- Vibration resistance

- Pollution degree

Advanced Protection Features

Smart Protection

- Monitoring Capabilities

- Current sensing

- Temperature monitoring

- Status indication

- Fault recording

- Remote monitoring

- Predictive Maintenance

- Wear indicators

- Life expectancy calculation

- Performance trending

- Maintenance scheduling

- Failure prediction

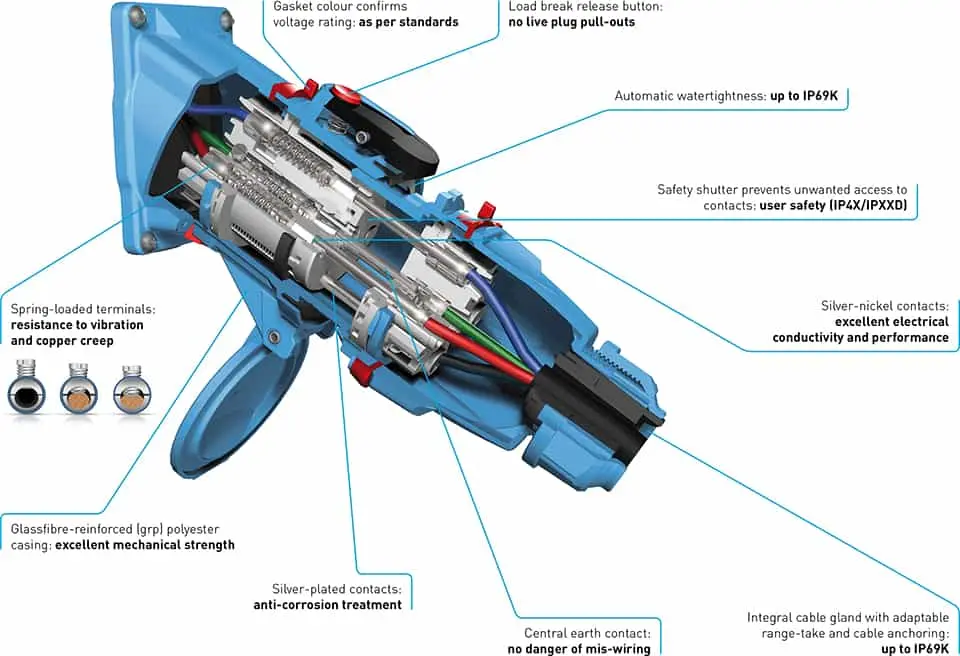

Installation and Maintenance

Best Practices

- Installation Guidelines

- Mounting requirements

- Ventilation needs

- Terminal connections

- Accessibility considerations

- Safety clearances

- Maintenance Protocol

- Regular inspection

- Testing procedures

- Replacement criteria

- Documentation requirements

- Safety procedures

Economic Considerations

Cost Analysis

- Initial Investment

- Component costs

- Installation expenses

- System integration

- Certification fees

- Training requirements

- Lifecycle Costs

- Maintenance expenses

- Replacement costs

- Downtime reduction

- Energy efficiency

- System reliability

Future Developments

Emerging Technologies

- Smart Protection

- IoT integration

- Remote monitoring

- Predictive analytics

- Digital twins

- Artificial intelligence

- Sustainable Solutions

- Energy efficiency

- Material optimization

- Environmental impact

- Recyclability

- Carbon footprint

System Integration Guidelines

Design Implementation

- Circuit Layout

- Component placement

- Heat management

- EMC considerations

- Access requirements

- Safety spacing

- Protection Coordination

- Time-current analysis

- Energy coordination

- Backup protection

- Selective operation

- Fault management

Performance Optimization

Efficiency Enhancement

- Power Loss Reduction

- Contact resistance

- Thermal management

- Connection quality

- Material selection

- Design optimization

- Reliability Improvement

- Component selection

- Environmental protection

- Stress reduction

- Quality control

- Testing procedures

Conclusion: The Future of Inverter Protection

Cooper Bussmann Inverter continues to lead in developing advanced protection solutions for modern inverter systems. Their commitment to innovation and quality ensures:

Key Benefits

- Enhanced system reliability

- Improved safety standards

- Reduced maintenance costs

- Extended equipment life

- Better system protection

Future Outlook

- Continued technological advancement

- Enhanced integration capabilities

- Improved monitoring systems

- Greater energy efficiency

- Advanced protection features

Cooper Bussmann Inverter Note: Always consult Cooper Bussmann’s technical documentation and local electrical codes for specific application requirements.