Blog

Fuse Introduction: Working Principle & Selection Factors

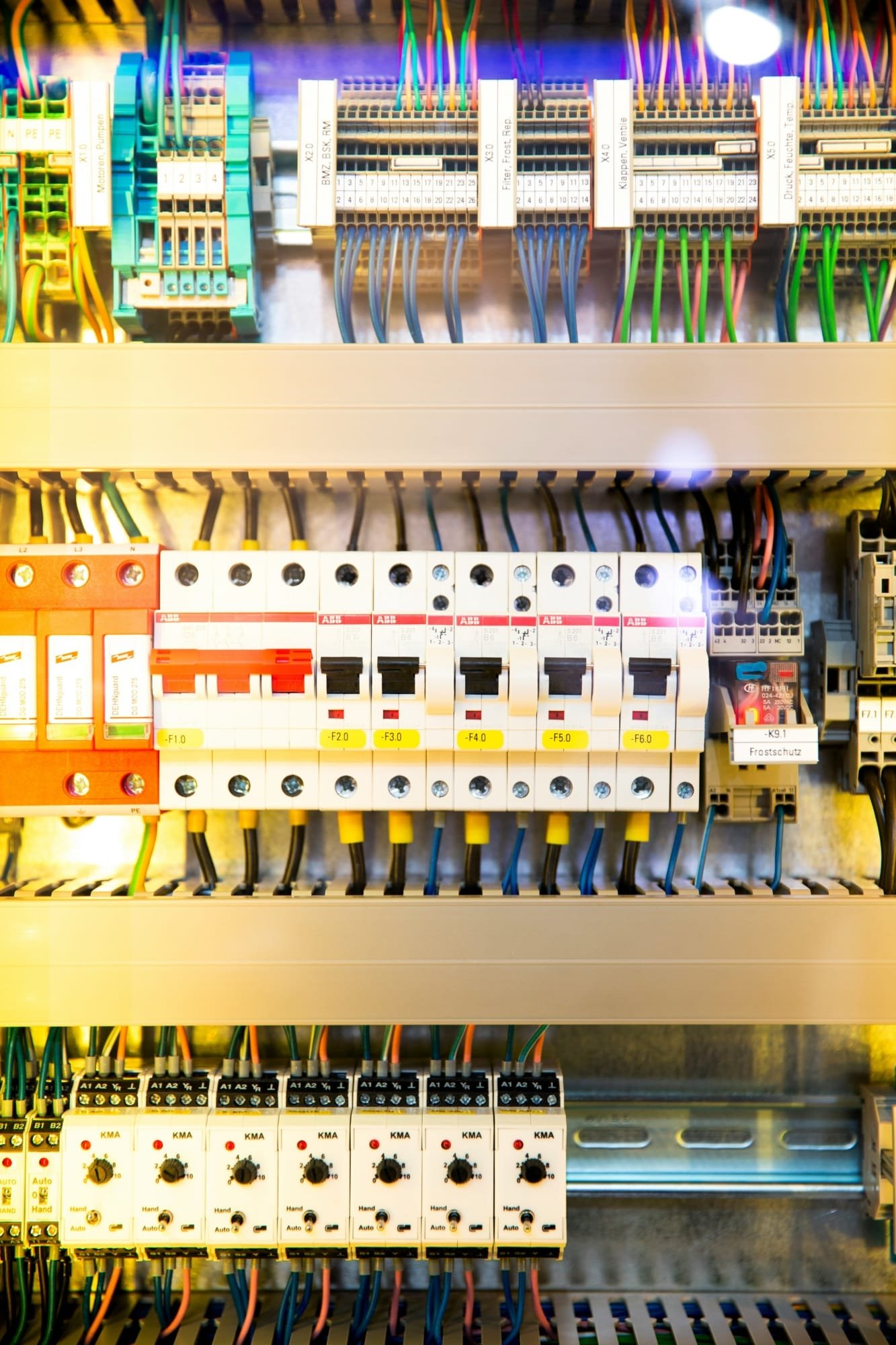

Fuse Introduction: The Unsung Heroes of Electrical Safety

Fuses are crucial components in electrical systems, acting as silent guardians that protect circuits from overcurrent and overload. This article delves into the world of fuses, exploring their functions, principles, types, and selection criteria.

The Role of Fuses in Electrical Circuits

Primary Functions

- Normal operation: Fuses serve as connectors in electrical circuits.

- Abnormal conditions: Fuses act as safety devices, melting to safely disconnect and protect the circuit during overloads.

Working Principle

When a fuse carries current, it generates heat. Under normal conditions, this heat dissipates to the environment. However, during an overload, the accumulated heat causes the fuse element to melt, breaking the circuit and protecting connected devices.

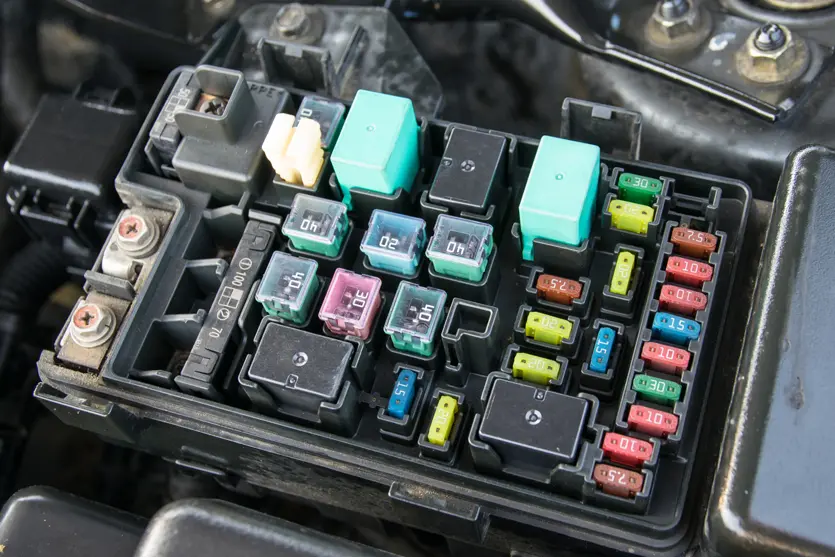

Types of Fuses

By Physical Dimensions

Fuses come in various sizes, including φ2, φ3, φ4, φ5, and φ6.

By Time-Current Characteristics

- Fast-acting

- Medium time-delay

- Time-delay

By Breaking Capacity

- Low breaking capacity

- High breaking capacity

By Safety Standards

- UL/CSA (North America)

- IEC (China, Europe)

- MIT/KTL (Japan/Korea)

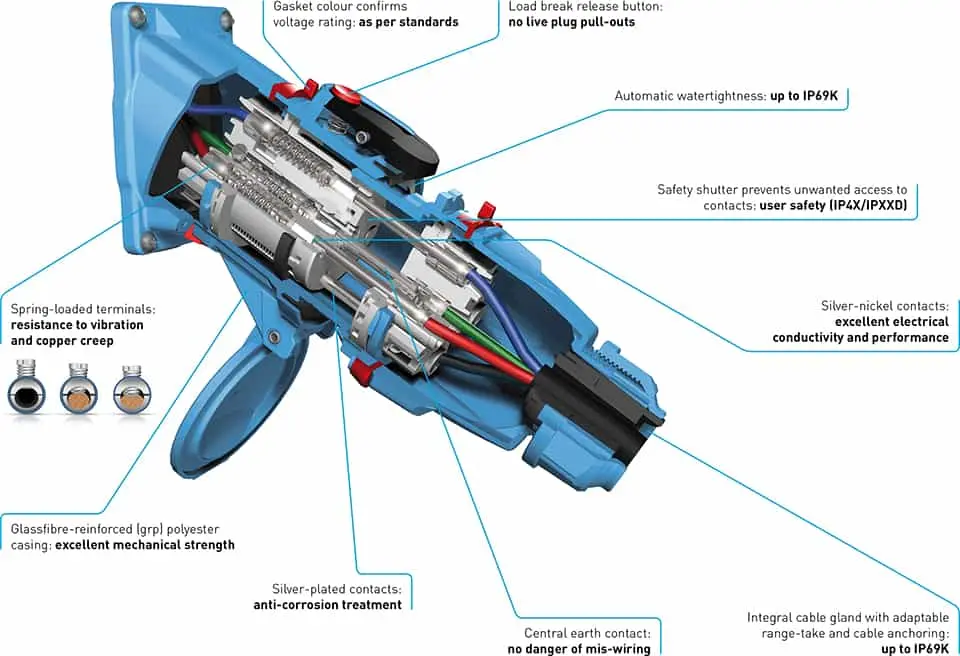

Key Terminology in Fuse Technology

Rated Current

The nominal working current of a fuse under normal conditions.

Rated Voltage

The maximum voltage a fuse can safely withstand when interrupting a circuit.

Breaking Capacity

The maximum current a fuse can safely interrupt without causing hazards.

Overload Capacity

The maximum overload current a fuse can withstand for a specified time without melting.

Time-Current Characteristic

The relationship between the current applied to a fuse and the time it takes to melt.

I²t Value

The nominal energy required to melt and partially vaporize a fuse.

Voltage Drop

The voltage difference across a fuse under steady-state conditions.

Temperature Rise

The difference between the fuse surface temperature and the initial temperature under specific current conditions.

Safety Standards and Markings

UL/CSA Standards

- UL/CSA LIST

- UL/CSA RECOGNIZED

JIS Standards

- T mark

- PSE mark

KTL Standards

- K mark

IEC Standards

- CCC (China)

- SEMKO (Sweden)

- VDE (Germany)

- BSI (UK)

- IMQ (Italy)

Factors Affecting Fuse Lifespan

Operating Environment Temperature

High temperatures can significantly reduce fuse lifespan due to diffusion, oxidation, and thermal stress.

Pulse Currents

Repeated pulse impacts can accelerate fuse aging through thermal cycling.

Other Factors

Contact resistance with fuse holders and the length and cross-sectional area of connecting wires can impact fuse performance.

Fuse Selection Guidelines

Step-by-Step Selection Process

- Determine required safety certification

- Choose appropriate fuse dimensions

- Select fuse type based on circuit characteristics

- Determine rated voltage

- Calculate minimum rated current

- Determine minimum I²t value

- Finalize fuse rated current

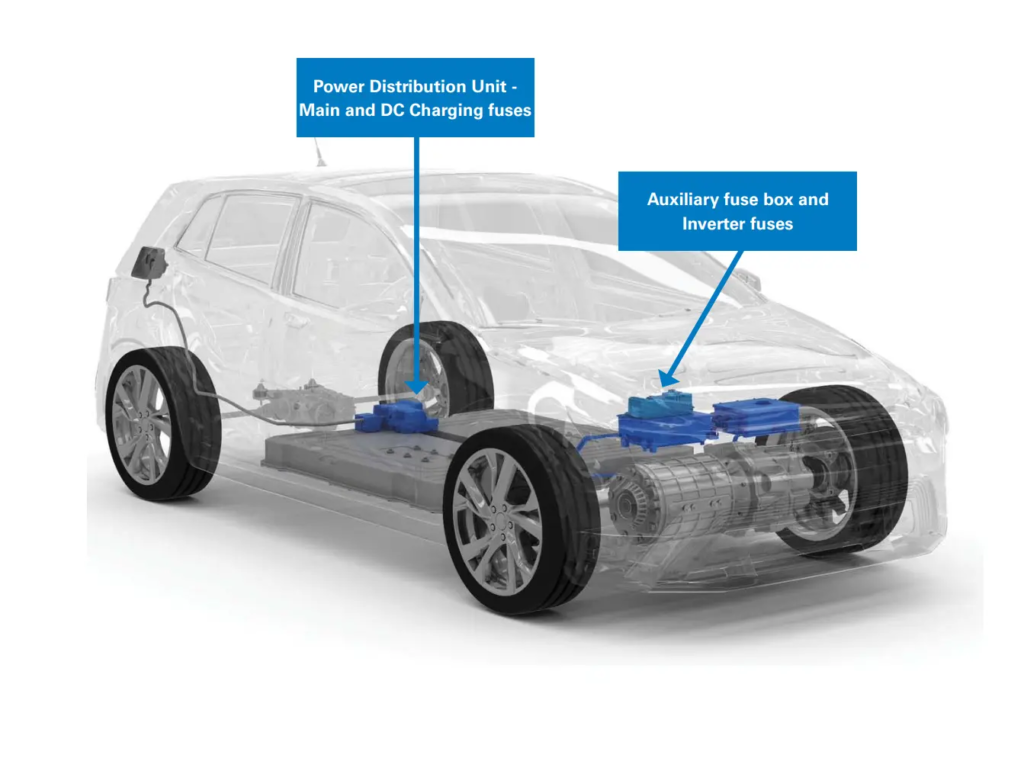

Common Applications of Different Fuse Types

Fast-Acting Fuses

Suitable for circuits with relatively constant current or small surge currents.

Time-Delay Fuses

Ideal for circuits with normal surge currents and no shock-sensitive components.

High Breaking Capacity Fuses

Used in circuits where large short-circuit currents may occur.

Important Considerations When Using Fuses

- Ensure the fuse’s rated voltage exceeds the protected circuit’s input voltage.

- Apply appropriate derating factors based on standards and operating conditions.

- Consider environmental temperature effects on fuse performance.

- Match fuse breaking capacity to potential short-circuit currents in the protected circuit.

- Ensure surge I²t of the protected circuit is less than 20% of the fuse’s rated I²t.

Conclusion

Fuses play a critical role in electrical safety, protecting circuits and devices from potential damage due to overcurrent and overload conditions. Understanding fuse characteristics, selection criteria, and proper application is essential for designing safe and reliable electrical systems.