Blog

Which Parameters Of Bussmann Inline Car Fuse Would To Know?

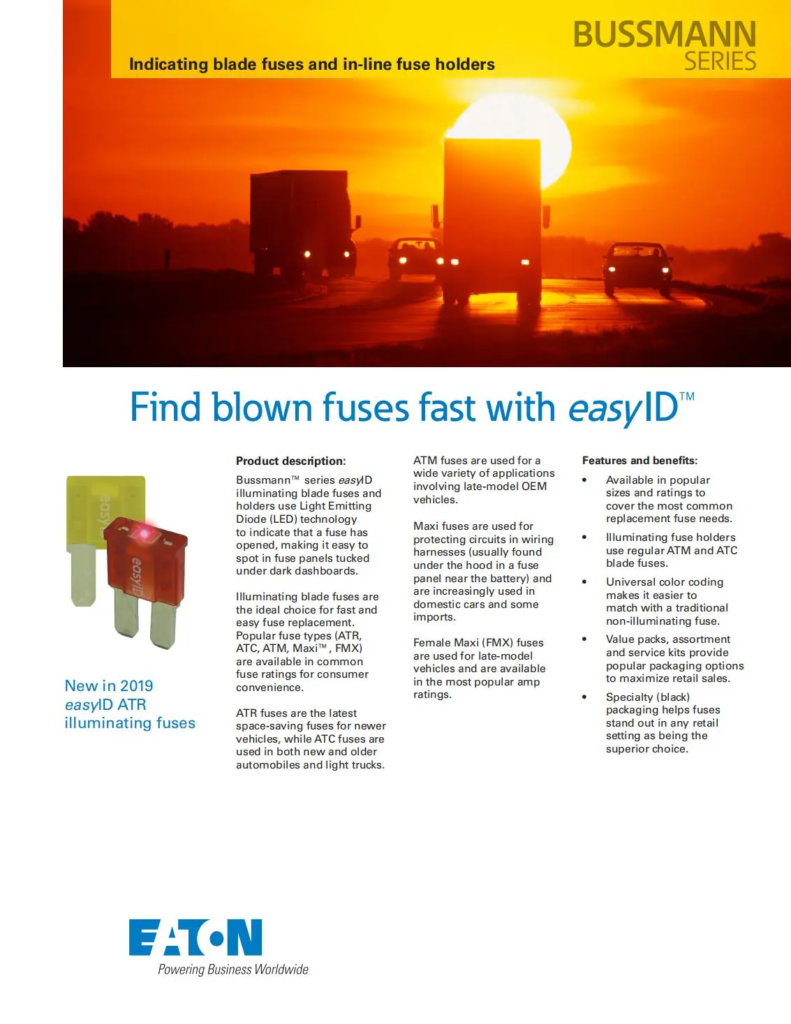

Bussmann Inline Car Fuse: The Unsung Hero of Automotive Electrical Safety

The Critical Role of Electrical Protection in Modern Vehicles

In the complex ecosystem of automotive electronics, the Bussmann Inline Car Fuse stands as a critical guardian of electrical integrity. This seemingly simple component plays a pivotal role in protecting sophisticated vehicle electrical systems from potential catastrophic failures.

Understanding the Fundamental Science of Automotive Fuse Protection

Electrical Fault Mechanism

Automotive electrical systems are vulnerable to various fault conditions:

- Overcurrent scenarios

- Short circuit events

- Unexpected load fluctuations

- Thermal stress conditions

- Electrical system degradation

Fuse Operating Principles

The Bussmann Inline Car Fuse operates on fundamental electromagnetic principles:

- Thermal Response

- Designed with a precisely calibrated metal strip

- Melts at predetermined current thresholds

- Instantaneous circuit interruption

- Material Engineering

- Special alloy compositions

- Optimized melting point characteristics

- Predictable thermal expansion properties

Technical Specifications of Bussmann Inline Car Fuses

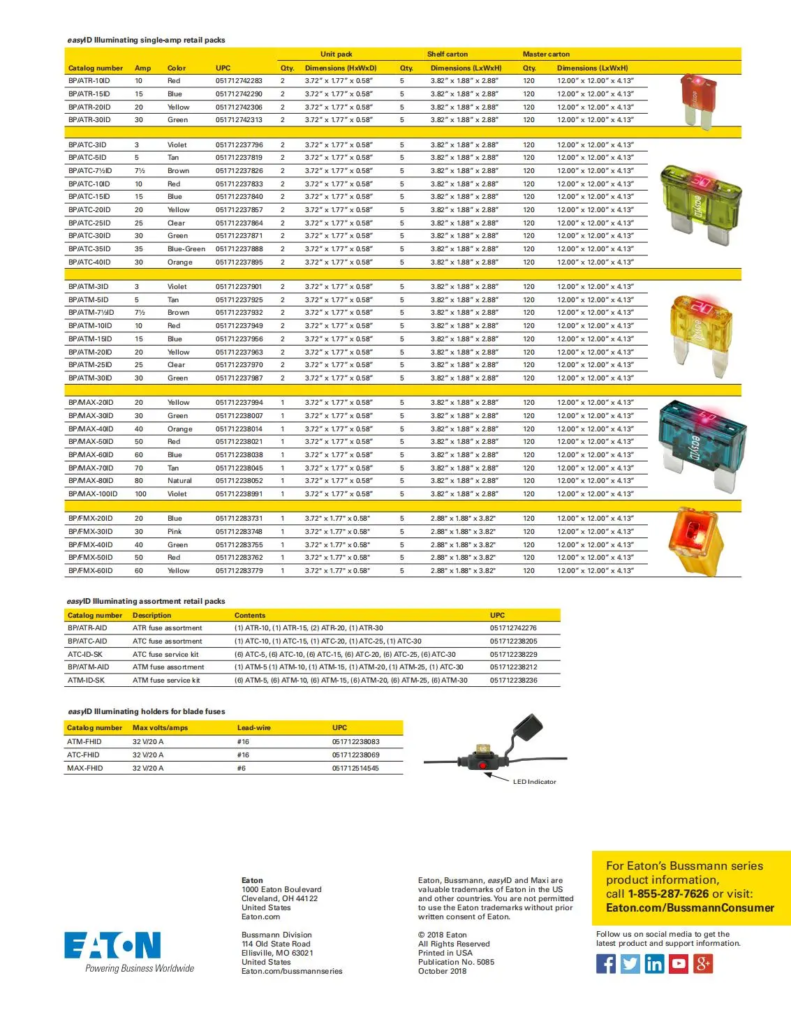

Electrical Ratings

- Voltage Range: Typically 32VDC

- Current Ratings:

- Standard ranges from 1A to 40A

- Specialized applications up to 60A

- Temperature Performance

- Operational range: -40°C to +125°C

- Consistent performance across extreme conditions

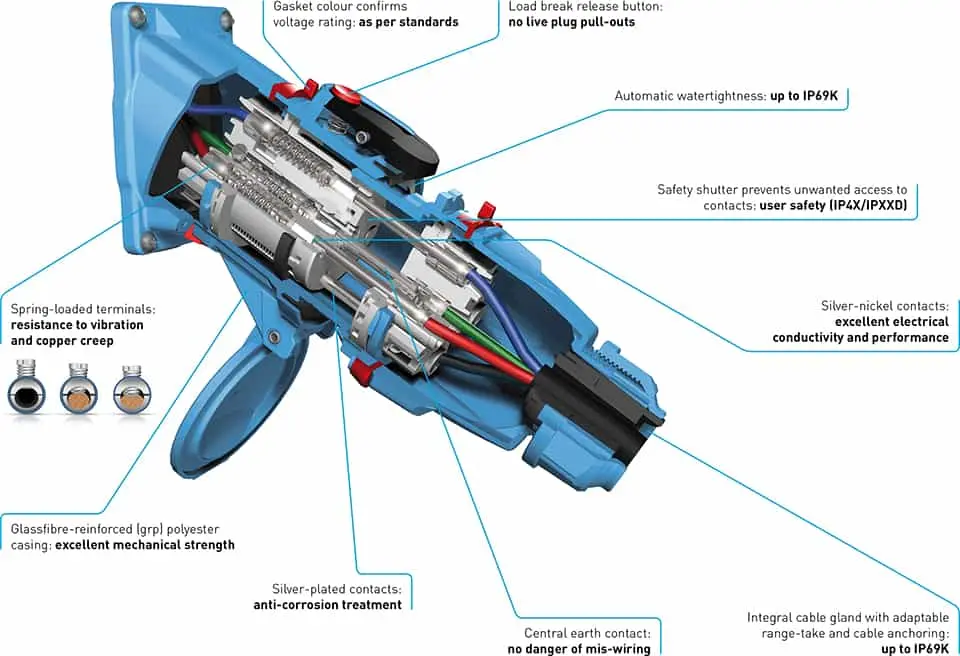

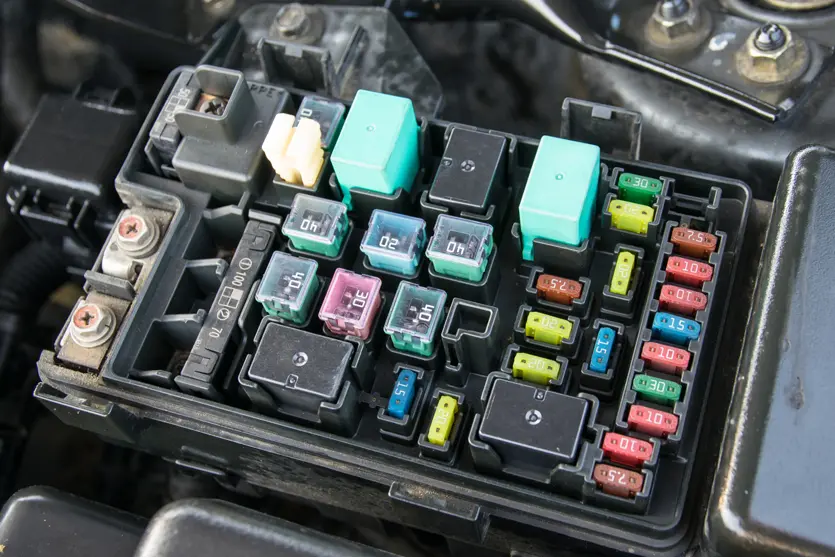

Physical Characteristics

- Dimensional Standardization

- Blade-type design

- Color-coded for easy identification

- Compact form factor

- Construction Materials

- High-grade thermoplastic housing

- Copper alloy conductive elements

- Corrosion-resistant contacts

- UV-stabilized external components

Advanced Protection Mechanisms

Fault Detection and Interruption

- Overcurrent Protection

- Rapid response to excessive current

- Prevents wire heating and potential fire risks

- Protects sensitive electronic components

- Short Circuit Mitigation

- Immediate circuit isolation

- Prevents cascading electrical failures

- Minimizes potential vehicle electrical system damage

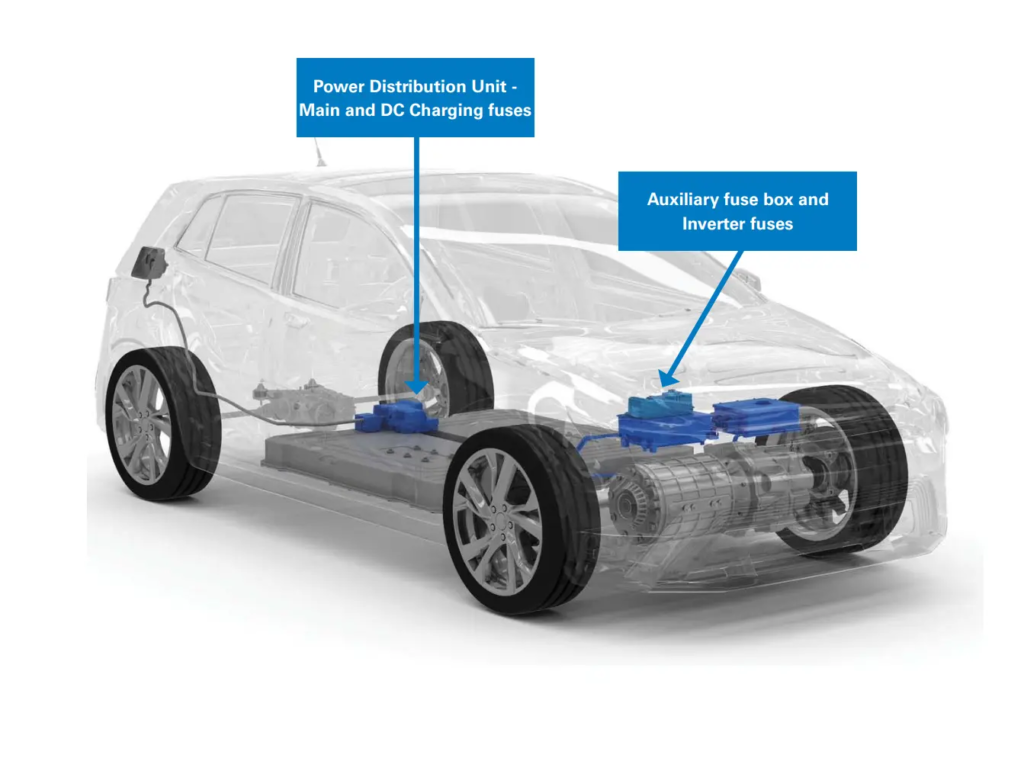

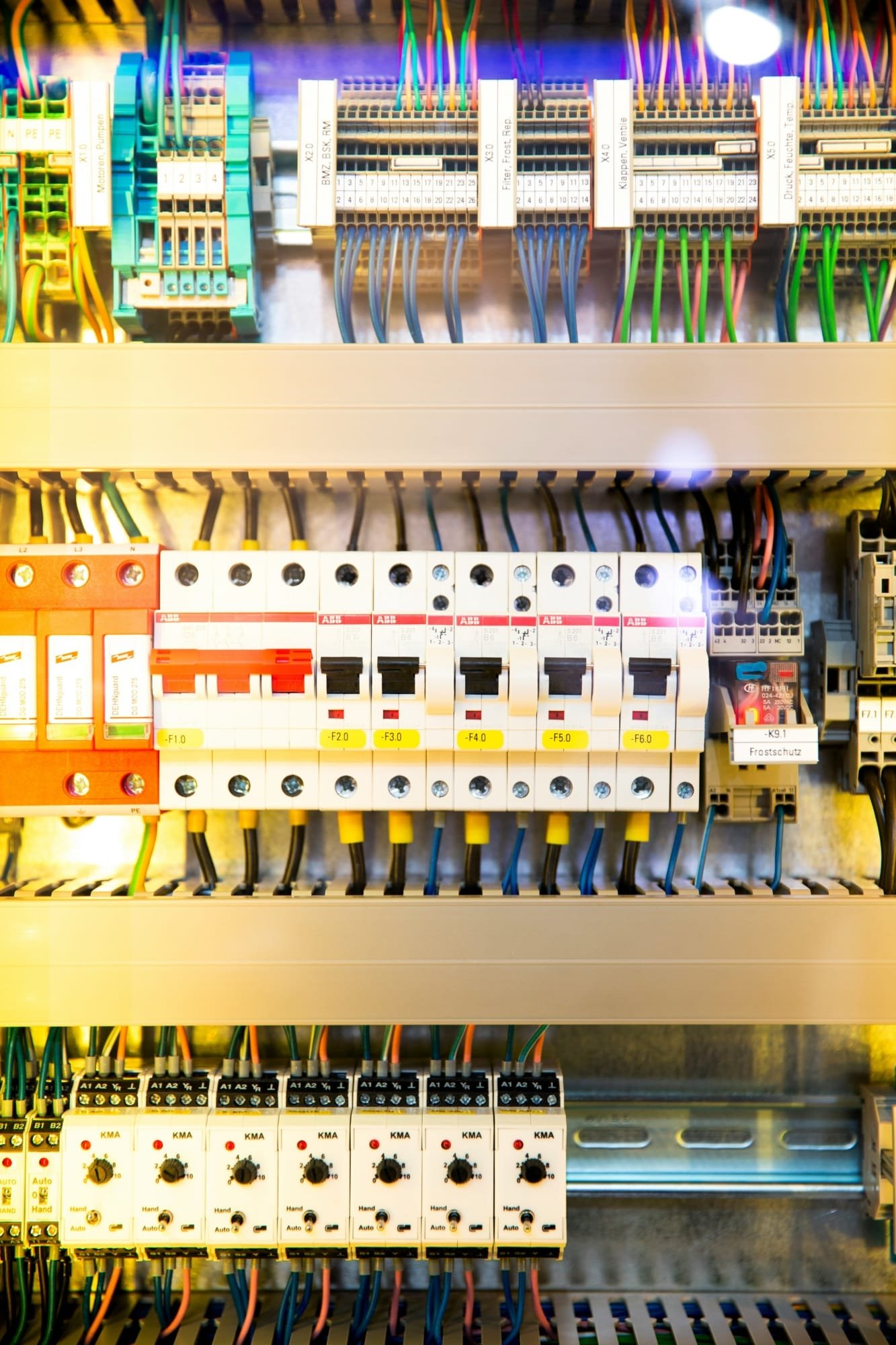

Application Domains in Automotive Systems

Critical Electrical Zones

- Engine Management Systems

- ECU protection

- Sensor circuit safeguarding

- Fuel injection control

- Interior Electrical Networks

- Dashboard electronics

- Infotainment systems

- Climate control circuits

- Lighting management

- Auxiliary Power Systems

- Aftermarket accessories

- Communication equipment

- Specialized vehicle modifications

Installation and Maintenance Considerations

Professional Installation Guidelines

- Preparation Steps

- Verify circuit requirements

- Select appropriate amperage rating

- Inspect mounting locations

- Ensure proper wire connections

- Best Practices

- Use manufacturer-recommended tools

- Follow precise torque specifications

- Verify electrical continuity

- Conduct comprehensive system testing

Diagnostic and Replacement Protocols

- Visual Inspection Techniques

- Check for discoloration

- Examine physical integrity

- Look for signs of thermal stress

- Replacement Criteria

- Regular preventive replacement intervals

- After significant electrical events

- When system modifications occur

Comparative Analysis with Alternative Protection Devices

Circuit Breaker vs. Fuse

Bussmann Inline Fuse Advantages

- Lower cost

- Faster response time

- Simpler replacement process

- More precise current interruption

Electronic Protective Devices

- More predictable failure modes

- Lower maintenance requirements

- Consistent performance characteristics

Emerging Trends in Automotive Electrical Protection

Technological Innovations

- Smart Fuse Technologies

- Integrated diagnostic capabilities

- Real-time monitoring features

- Predictive maintenance potential

- Material Science Advancements

- Nanotechnology-enhanced compositions

- Improved thermal management

- Enhanced durability

Future Outlook

- Integration with vehicle electronic systems

- Advanced diagnostic capabilities

- Improved environmental resistance

- Lighter, more efficient designs

Selection Criteria for Optimal Fuse Specification

Factors to Consider

- Electrical Load Requirements

- Continuous current rating

- Inrush current characteristics

- Voltage drop considerations

- Environmental Factors

- Operating temperature range

- Humidity resistance

- Vibration tolerance

- Chemical exposure potential

Maintenance and Troubleshooting

Common Failure Modes

- Electrical Overload

- Symptoms

- Diagnostic procedures

- Preventive strategies

- Corrosion and Degradation

- Detection methods

- Mitigation techniques

- Replacement recommendations

Conclusion: The Critical Role of Precision Protection

The Bussmann Inline Car Fuse represents more than a simple safety device – it’s a sophisticated guardian of automotive electrical systems. Its complex engineering ensures the reliability, safety, and performance of modern vehicle electronics.

Key Takeaways

- Essential protection for automotive electrical systems

- Precision-engineered for reliable performance

- Critical component in vehicle safety infrastructure

- Continuous technological evolution

Disclaimer: Always consult professional automotive technicians and follow manufacturer recommendations when working with vehicle electrical systems.