Blog

Bussmann Fuse Selection Guide – Official Guide

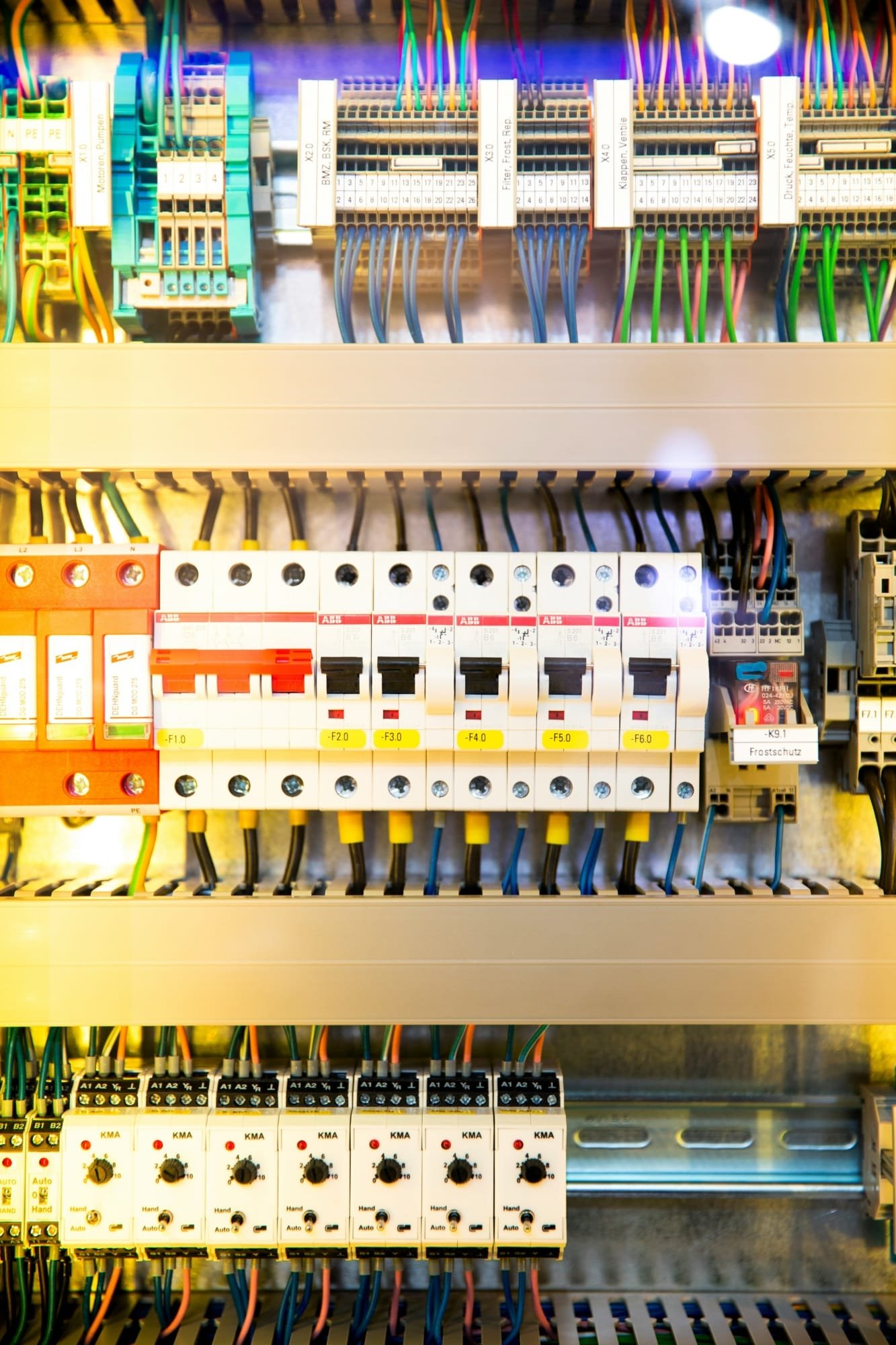

The Complete Guide to Selecting Bussmann Fuse Selection Guide: A Professional’s Handbook

Introduction: Why Proper Fuse Selection Matters

In the world of electrical protection, choosing the right fuse isn’t just about matching numbers – it’s about ensuring safety, reliability, and optimal system performance. Bussmann, a leader in circuit protection solutions, offers an extensive range of fuses, but selecting the right one requires careful consideration of multiple factors.

Understanding Basic Fuse Parameters

Voltage Ratings

Before diving into specific fuse types, it’s crucial to understand that voltage ratings are non-negotiable parameters. A fuse rated for 250V should never be used in a 600V system, regardless of its current rating. Bussmann fuses typically display their voltage ratings prominently, with common ratings including:

- 250VAC

- 600VAC

- 125VDC

- 32VDC (automotive applications)

Current Ratings

Current ratings must be selected based on:

- Normal operating current

- Startup current requirements

- Ambient temperature conditions

- Circuit loading patterns

Types of Bussmann Fuses and Their Applications

1. Fast-Acting Glass Tube Fuses

Applications:

- Laboratory equipment

- Test instrumentation

- Consumer electronics

- Medical devices

Key Features:

- Quick response to overloads

- Clear visual indication of failure

- Available in ratings from 0.1A to 30A

- Maximum voltage rating of 250VAC

2. Low-Peak Current-Limiting Fuses

Applications:

- Industrial machinery

- Motor protection

- Distribution systems

- Power conversion equipment

Key Features:

- Reduced let-through energy

- High interrupting ratings

- Available in ratings up to 600A

- Voltage ratings up to 600VAC

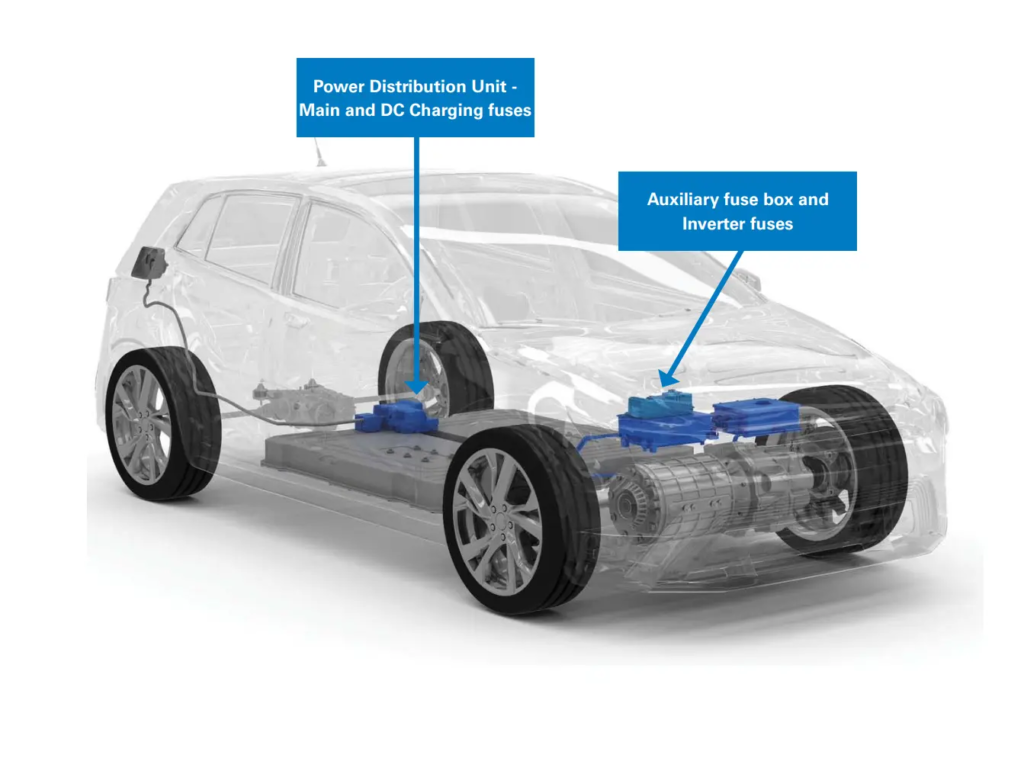

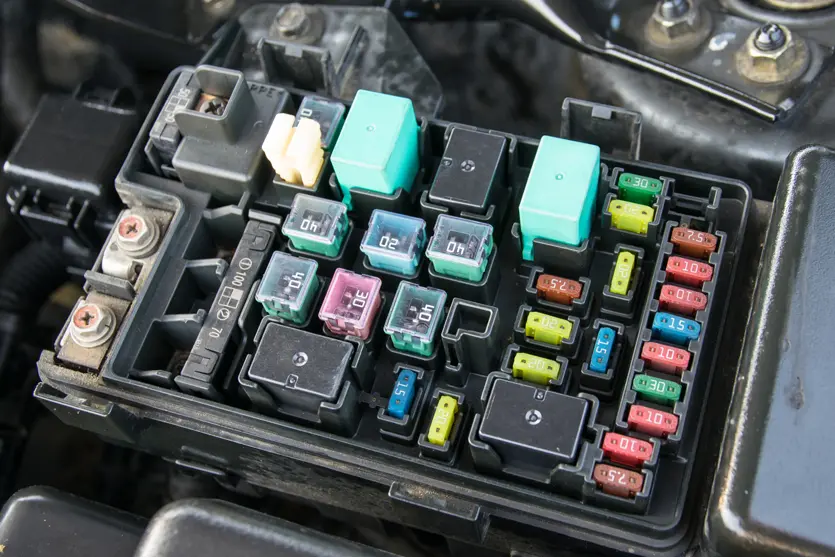

3. Automotive Fuses

Applications:

- Vehicle electrical systems

- Mobile equipment

- Low-voltage DC systems

- Marine applications

Key Features:

- Blade-style design

- Color-coded for easy identification

- Ratings from 1A to 80A

- Maximum voltage of 32VDC

Selection Methodology: A Step-by-Step Approach

Step 1: Circuit Analysis

- Determine normal operating current

- Calculate maximum fault current

- Identify voltage requirements

- Consider environmental conditions

Step 2: Application Requirements

- Speed of response needed

- Ultra-fast acting

- Fast-acting

- Time-delay

- Space constraints

- Mounting requirements

- Visual indication needs

Step 3: Safety and Certification Requirements

- Check required certifications:

- UL Listed

- CSA Certified

- VDE Approved

- CE Marked

- Verify compliance with:

- National Electrical Code (NEC)

- International standards

- Industry-specific requirements

Environmental Considerations

Temperature Derating

Temperature significantly affects fuse performance. Consider:

- Ambient temperature range

- Ventilation conditions

- Proximity to heat sources

- Required derating factors

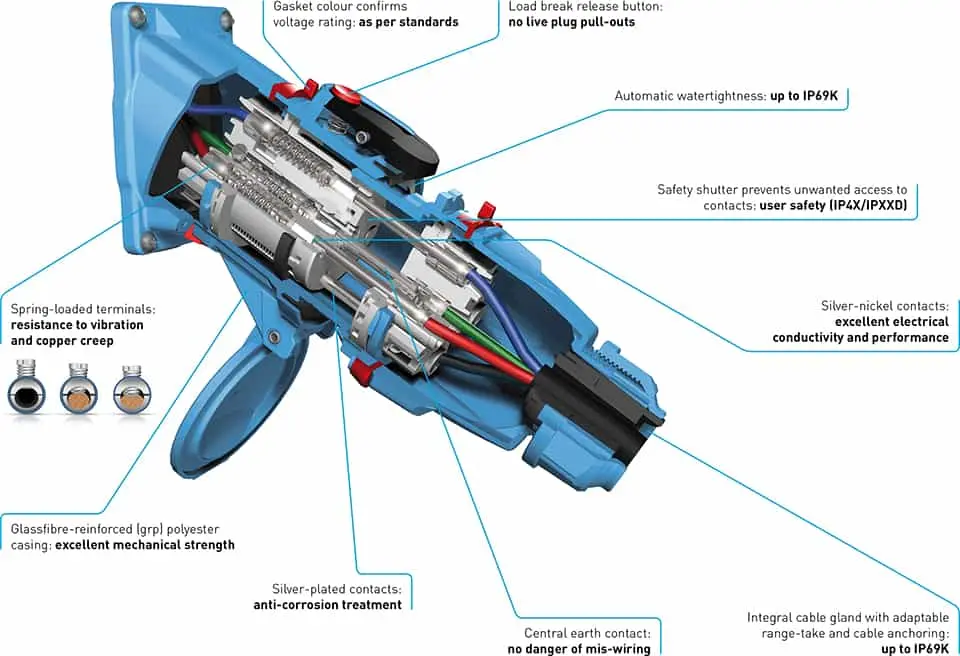

Environmental Protection

Some applications require additional protection against:

- Moisture

- Dust

- Vibration

- Corrosive atmospheres

Advanced Selection Considerations

Coordination and Selectivity

For systems with multiple fuses:

- Ensure proper coordination between fuses

- Verify selective operation under fault conditions

- Consider time-current characteristics

- Analyze backup protection requirements

Energy Efficiency

Modern fuse selection should consider:

- Energy losses during normal operation

- Impact on system efficiency

- Life-cycle costs

- Maintenance requirements

Best Practices for Installation and Maintenance

Installation Guidelines

- Use appropriate fuse holders

- Ensure proper terminal connections

- Maintain adequate ventilation

- Follow manufacturer’s torque specifications

Maintenance Recommendations

- Regular visual inspections

- Thermal scanning

- Resistance measurements

- Replacement scheduling

Common Selection Mistakes to Avoid

1. Oversizing Fuses

- Reduced protection effectiveness

- Increased let-through energy

- Potential equipment damage

2. Incorrect Type Selection

- Using fast-acting where time-delay is needed

- Mixing DC and AC rated fuses

- Improper interrupting rating

3. Ignoring Environmental Factors

- Temperature considerations

- Altitude derating

- Exposure to elements

Conclusion: Ensuring Long-Term Protection

Selecting the right Bussmann fuse is a critical decision that impacts system reliability, safety, and performance. By following this comprehensive guide and considering all relevant factors, you can make informed choices that provide optimal protection for your electrical systems.

Remember that fuse selection is not just about meeting minimum requirements – it’s about providing reliable, long-term protection that ensures both safety and system availability. When in doubt, always consult Bussmann’s technical support or a qualified electrical engineer.

Note: This guide serves as a general reference. Always consult current Bussmann catalogs, technical data sheets, and applicable codes and standards for specific application requirements.